Liran Silbermann, Marketing Leo AI

Feb 10, 2026

Your new SOLIDWORKS engineer has a master's degree and 3 years of experience at a similar company. His resume is perfect. So why will it take him 9-12 months to become productive on your team?

The answer isn't his skills or motivation. It's everything he doesn't know yet. Your product line history. Your design standards. Your PLM workflows. The vendor who always ships late. Why that assembly sequence is the only one that works. The material combination that failed testing in 2020.

According to research from the Society for Human Resource Management, the average cost of a bad hire is five times their annual salary. But slow onboarding of good hires costs almost as much. At $140K for a senior mechanical engineer, every month of partial productivity costs you $5,000-$10,000 in lost output, plus the senior engineer time spent answering questions.

For a 50-person engineering team with 20% annual turnover, slow onboarding costs you $500K-$900K per year.

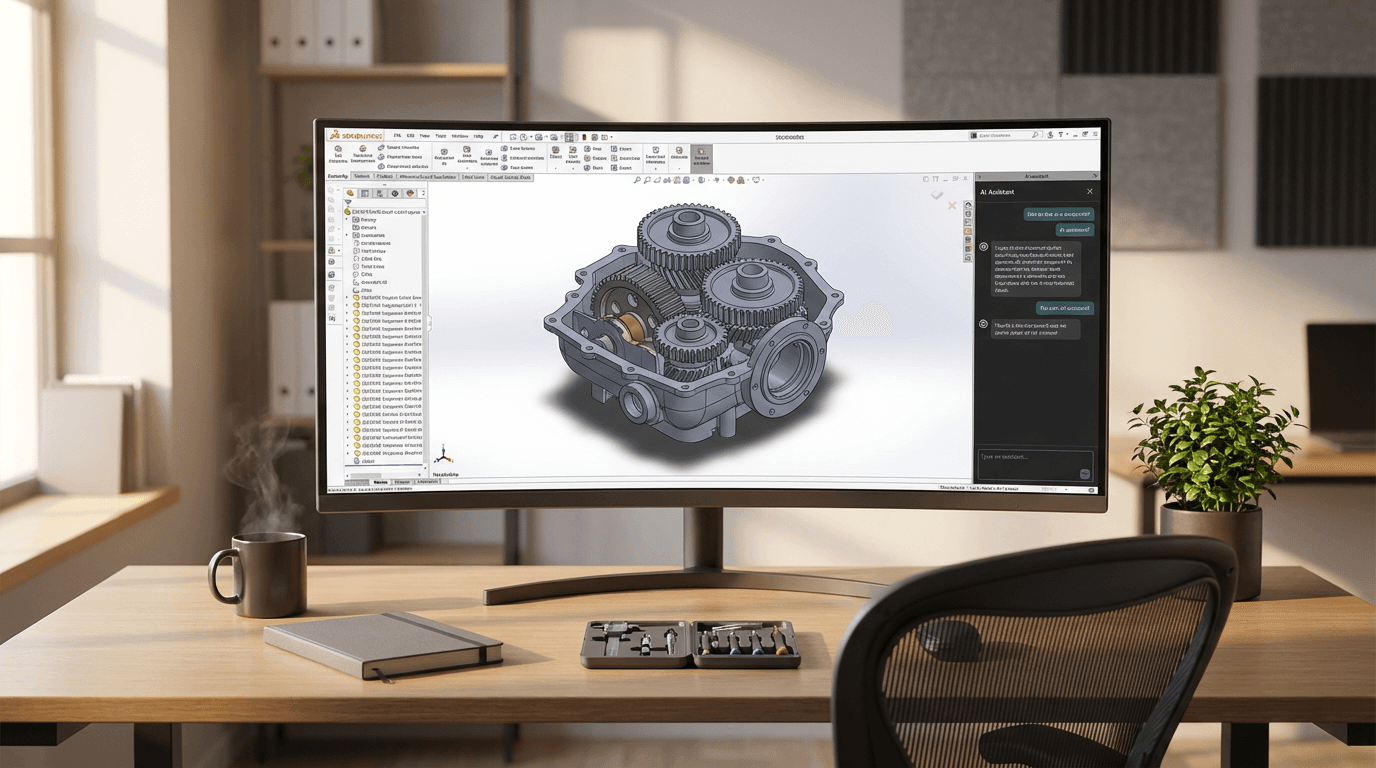

This article shows you how enterprise engineering teams cut SOLIDWORKS onboarding time by 60%, using proven frameworks and AI-powered knowledge management tools.

The Real Cost of Traditional SOLIDWORKS Onboarding

Industry benchmarks paint a consistent picture. Junior engineers take 18-24 months to reach full productivity. Senior engineers with relevant experience take 9-12 months. Even rockstar hires with perfect backgrounds need 6-9 months.

Here's what takes so long:

Systems and Tools (2-4 weeks): Getting access to SOLIDWORKS, PDM, PLM, email, Slack, VPN, design libraries. Learning where everything lives. Understanding file naming conventions. This is the easy part.

Company-Specific Knowledge (3-6 months): Learning your product lines, understanding your design standards, recognizing your assembly patterns, knowing your vendor relationships, understanding your testing requirements. This requires exposure to actual projects.

Tribal Knowledge (6-18 months): Why certain design decisions were made. What approaches have failed before. Which workarounds solve recurring problems. Who to ask for specific expertise. This is never written down anywhere.

Independent Problem-Solving (9-24 months): Knowing enough to solve problems without escalation. Recognizing patterns from past projects. Making good decisions without constant supervision. This is what "fully productive" actually means.

Key Insight: The bottleneck isn't CAD skills. It's access to institutional knowledge that exists only in people's heads and scattered across disconnected systems.

A McKinsey study found that engineers spend 6-8 hours per week searching for information. For new engineers, that number doubles. That's 12-16 hours per week asking questions, searching files, and interrupting colleagues.

At $85/hour loaded cost, that's $52,000-$68,000 per year just in search time. For a single engineer.

Understanding the phases helps you identify where acceleration is possible.

Phase 1: Systems and Tools (Weeks 1-2)

What happens: Access provisioning, software installation, basic orientation to systems.

Traditional approach: IT tickets, manual walkthroughs, shadowing someone for a day.

Accelerated approach: Pre-provisioned accounts, automated onboarding checklist, self-service knowledge base with video tutorials, AI assistant that answers basic questions.

Time savings possible: 30-40% (from 2-3 weeks to 1-2 weeks)

Phase 2: Product Knowledge (Weeks 3-8)

What happens: Learning product lines, understanding design intent, recognizing component relationships, knowing assembly patterns.

Traditional approach: Reading old documentation (if it exists), reviewing past projects, asking senior engineers constant questions.

Accelerated approach: Structured product knowledge base, design pattern library, AI-powered search across all past projects, guided project reviews with specific learning objectives.

Time savings possible: 50-60% (from 8-12 weeks to 4-6 weeks)

Phase 3: Design Autonomy (Weeks 9-16)

What happens: Working on real designs with minimal supervision, making decisions independently, solving problems without escalation.

Traditional approach: Trial and error, frequent reviews, lots of rework, gradual confidence building.

Accelerated approach: AI assistant that provides instant answers to "how did we handle this before" questions, proactive alerting about potential mistakes, access to design rationales and past decisions, automated knowledge capture from senior engineers.

Time savings possible: 60-70% (from 12-16 weeks to 4-6 weeks)

Phase 4: Full Productivity (Weeks 17+)

What happens: Contributing at the level of experienced team members, mentoring newer engineers, improving processes.

Traditional approach: Happens gradually over 18-24 months as engineer builds tribal knowledge through experience.

Accelerated approach: Continuous access to institutional knowledge through AI systems, systematic lessons learned capture, cross-project knowledge sharing.

Time savings possible: 50-65% (from 18-24 months to 6-9 months)

The Hiring Choice: Junior vs. Senior Engineer + AI Impact

When your veteran engineer retires, you face a choice. Here's what productivity timelines actually look like.

Capability | Junior (No AI) | Senior (No AI) | Junior + AI | Senior + AI |

Profile | Fresh grad, CAD basics | 8+ years relevant experience | Fresh grad, CAD basics | 8+ years relevant experience |

Basic SOLIDWORKS | 2-3 months | Already proficient | 3-4 weeks | Already proficient |

Your drawing standards | 3-4 months | 2-3 weeks | 4-6 weeks | 1-2 weeks |

Your PLM system | 4-6 months | 6-8 weeks | 6-8 weeks | 3-4 weeks |

Product line history | 8-12 months | 4-6 months | 2-3 months | 6-8 weeks |

Design decisions & rationale | 12-18 months | 6-9 months | 3-4 months | 2-3 months |

Proven workflows | 12+ months | 3-4 months | 2-3 months | 4-6 weeks |

"Why we don't do X" | 18+ months | 6-12 months | 3-5 months | 6-10 weeks |

Vendor relationships | 18-24 months | 6-9 months | 4-6 months | 2-3 months |

Spot repeat mistakes | 24+ months | 9-12 months | 4-6 months | 2-4 months |

Independent productivity | 18-24 months | 9-12 months | 6-9 months | 3-4 months |

Replaces retiring engineer | Never (60-70%) | 12-18 months (85%) | 9-12 months (80-85%) | 4-6 months (90-95%) |

What this reveals:

Even your best hire faces a massive knowledge gap. That stellar senior engineer with perfect experience? He still needs 9-12 months to become truly productive in your environment. He doesn't know why Design Team A stopped using that specific fastener in 2019. He wasn't in the room when Engineering decided to change that assembly sequence.

Junior engineers without AI support never fully catch up. After two years, they're still missing 30-40% of institutional knowledge.

AI levels the playing field. A junior engineer with AI-powered knowledge management reaches productivity in 6-9 months instead of 18-24 months. That's a 12-18 month time savings at $75K salary, or $75K-$112K in recovered productivity.

AI supercharges your best hires. That expensive senior engineer you recruited? With AI, he's independently productive in 3-4 months instead of 9-12 months. He retains 90-95% of institutional knowledge instead of 85%. You get ROI on that six-figure salary much faster.

Real Example: A precision manufacturing company hired a senior mechanical engineer with 12 years of experience in similar products. With Leo AI providing instant access to 15 years of design rationale and past decisions, he was solving complex assembly problems independently by month 3 instead of the typical 9-month timeline.

Strategy 1: Build a Searchable Design Knowledge Base

Traditional documentation fails because engineers don't write it and don't read it. The solution isn't more documentation, it's better knowledge capture and retrieval.

What works:

Capture knowledge automatically from PDM check-in comments, email discussions, and design reviews

Make it searchable by design context, not just keywords

Embed answers in workflow (inside SOLIDWORKS, not a separate system)

Use AI to understand engineering terminology and product relationships

Implementation: Start with high-value knowledge domains like recurring design problems, vendor relationships, and common mistakes. Use AI-powered knowledge assistants that learn from existing PDM data and email archives.

Strategy 2: Create Progressive Complexity Assignments

Don't throw new engineers into complex projects immediately. Design a graduated path.

Week 1-2: Simple modifications to existing designs (change dimensions, swap components)

Week 3-6: Component-level designs with clear requirements and examples

Week 7-12: Sub-assembly designs with guidance from AI knowledge base

Week 13+: Full assembly ownership with decreasing supervision

Key principle: Each assignment should require learning one new thing while applying previously learned concepts. The AI assistant provides scaffolding that gradually reduces as competence increases.

Strategy 3: Implement "Office Hours" Instead of Constant Interruptions

Senior engineers lose 6-8 hours per week answering new hire questions. New engineers lose focus waiting for answers. Both problems are fixable.

What works:

Designated office hours for questions (2-3 scheduled blocks per week)

AI assistant answers 70-80% of questions instantly without human interruption

Questions that need human expertise get documented and added to knowledge base

Reduces context switching for senior engineers by 40-60%

Measurement: Track "questions asked per week" and "time to answer." As AI knowledge improves, questions decrease and answers get faster.

Strategy 4: Pair New Engineers with AI, Not Just People

The traditional buddy system pairs new engineers with experienced ones. This works but doesn't scale and creates bottlenecks.

Enhanced approach:

AI assistant is the primary resource for questions

Human buddy focuses on strategic guidance and relationship building

New engineer gets instant answers without interrupting colleagues

Human time is spent on high-value mentoring, not answering "where is the file" questions

Result: One experienced engineer can effectively support 5-6 new hires instead of 1-2.

Strategy 5: Measure and Optimize Continuously

You can't improve what you don't measure.

Key metrics to track:

Time to first independent design (target: 4-6 weeks with AI vs. 12-16 weeks traditional)

Questions asked per week (should decrease 60-70% by week 8)

Design revision rate (should match experienced engineers by month 6)

Knowledge base utilization (target: 80%+ of questions answered by AI)

Senior engineer time spent on onboarding support (should decrease 40-50%)

Quarterly review: Identify bottlenecks, update knowledge base, refine assignments, optimize AI training.

Tools and Technology That Accelerate Onboarding

Essential Foundation

SOLIDWORKS PDM Professional: Version control and design history

PLM System Integration: Product lifecycle context (integration guide)

Collaboration Platform: Slack or Teams for async communication

Accelerators

AI Knowledge Assistant: Leo AI provides instant answers from your design history without context switching

Video Knowledge Base: Screen recordings of complex workflows

Design Pattern Library: Proven approaches and templates

Automated Alerts: Flags potential mistakes based on past failures

Comparison: Traditional vs. AI-Assisted Onboarding

Aspect | Traditional Approach | AI-Assisted Approach |

Answer Time | 2-4 hours (wait for colleague) | Instant (AI responds in seconds) |

Knowledge Access | Fragmented across 5+ systems | Unified search across all sources |

Senior Engineer Burden | 6-8 hours/week per new hire | 2-3 hours/week per new hire |

Knowledge Retention | 60-70% after 12 months | 80-95% after 12 months |

Scalability | Limited (1 buddy per new hire) | High (AI supports unlimited users) |

Cost per New Hire | $50K-$90K in lost productivity | $15K-$30K in lost productivity |

Implementation Roadmap: 30-60-90 Days

Days 1-30: Foundation

Week 1:

Assess current onboarding process and pain points

Identify critical knowledge domains (what do new engineers ask most?)

Select AI knowledge management platform (evaluate options)

Week 2-3:

Connect AI system to PDM, email, and collaboration tools

Begin knowledge base indexing

Create progressive assignment framework

Week 4:

Pilot with next new hire

Track baseline metrics (questions asked, time to answer, senior engineer time)

Days 31-60: Optimization

Week 5-6:

Analyze pilot results and knowledge gaps

Enhance AI training with domain-specific content

Refine assignment progression based on actual performance

Week 7-8:

Expand to 2-3 concurrent new hires

Implement office hours structure

Create feedback loop for continuous knowledge base improvement

Days 61-90: Scaling

Week 9-10:

Roll out to all new hires

Train hiring managers on AI-assisted onboarding process

Establish quarterly optimization reviews

Week 11-12:

Measure results against traditional onboarding baseline

Calculate ROI (time saved, productivity gained, cost reduction)

Document best practices for company-wide adoption

Measuring Success: Key Performance Indicators

Track these metrics monthly to validate acceleration:

Time-based metrics:

Days to first independent design completion

Weeks to 80% productivity level

Months to full productivity equivalence

Quality metrics:

Design revision rate compared to experienced engineers

Number of repeated mistakes from knowledge gaps

Compliance with design standards

Efficiency metrics:

Questions asked per week (should decrease by 70% by week 8)

Senior engineer time spent on onboarding support

Knowledge base hit rate (% of questions answered by AI)

Business metrics:

Cost per new hire onboarding

Time-to-value for new engineering capacity

Knowledge retention after 6 and 12 months

ROI Calculation: Junior engineer at $75K takes 18 months to productivity traditionally. With AI-assisted onboarding, reaches productivity in 6 months. That's 12 months of accelerated value at partial productivity = $30K-$45K recovered per hire. For 10 hires per year: $300K-$450K annual value.

The Competitive Advantage of Faster Onboarding

Companies that master fast onboarding gain compounding advantages:

Talent acquisition: Offer new hires productivity and growth faster than competitors

Scaling capacity: Add engineering capacity 3x faster when business demands it

Knowledge resilience: Less vulnerable to turnover and retirements

Innovation velocity: Experienced engineers spend time innovating, not answering repetitive questions

Cost efficiency: Same team capacity at 40-60% lower onboarding cost

The engineering leaders who implement these systems first will build insurmountable knowledge advantages over the next 3-5 years.

Your Next Steps

Faster onboarding isn't about working harder. It's about giving new engineers instant access to the institutional knowledge that currently exists only in senior engineers' heads and scattered across disconnected systems.

Start here:

Calculate your current onboarding cost using your actual timelines and salaries

Identify your biggest knowledge bottlenecks (what do new engineers ask most?)

Pilot AI-assisted onboarding with your next hire

The technology exists today. The only question is whether you'll implement it before your competitors do.