Liran Silbermann, Leo AI Marketing

Feb 15, 2026

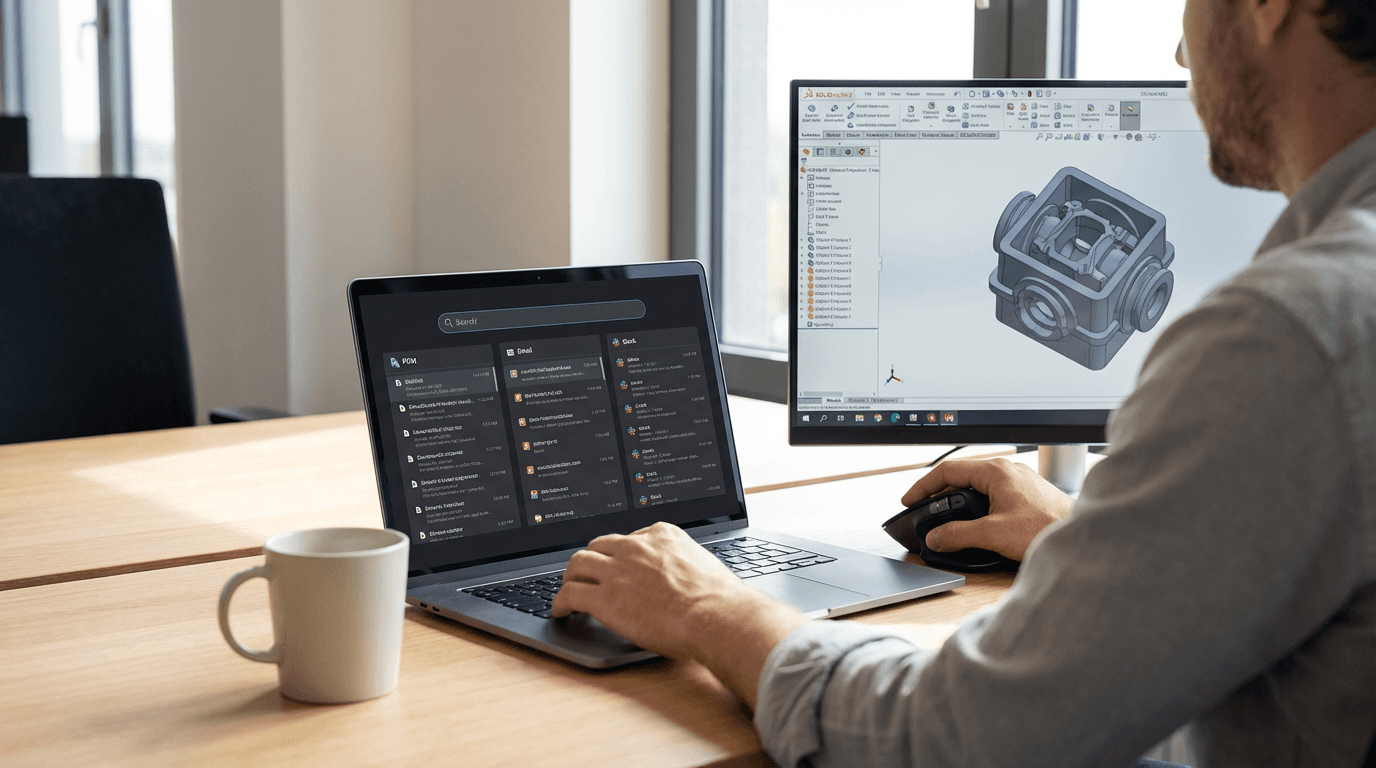

Your engineering team uses 12 different systems. None of them talk to each other. This is costing you millions.

Engineers spend 15-20% of their day searching for information across disconnected systems. They switch between SOLIDWORKS, PDM vault, email, Slack, SharePoint, ERP, PLM, specification documents, vendor portals, testing databases, and more. Each switch breaks concentration and wastes time.

According to research from McKinsey, poor integration between engineering tools costs large organizations $2-5M annually in lost productivity, data silos, version control issues, and collaboration friction.

For a 200-seat SOLIDWORKS deployment, the math is clear:

200 engineers × 6 hours/week searching × 48 weeks × $85/hour = $4,896,000 in annual waste

This article provides a comprehensive integration strategy for enterprise SOLIDWORKS environments, including architecture patterns, implementation roadmap, security requirements, and proven approaches for connecting PDM, PLM, collaboration tools, and AI-powered knowledge management.

The Enterprise SOLIDWORKS Ecosystem: Understanding the Layers

Before integrating, understand what you're connecting.

Core Layer: SOLIDWORKS CAD

What it does: 3D design, assemblies, drawings, simulations

Data generated:

Part files (.sldprt)

Assembly files (.sldasm)

Drawing files (.slddrw)

Design tables and configurations

Simulation results

Design intent and constraints

Integration requirements: Direct API access, file system integration, metadata extraction

Layer 1: PDM/PLM (Data Management)

What it does: Version control, workflow automation, access control, change management

Common systems:

SOLIDWORKS PDM Professional/Standard

PTC Windchill

Siemens Teamcenter

Dassault ENOVIA

Arena PLM

Custom PLM systems

Data managed:

CAD file versions and revisions

Bill of materials (BOM)

Check-in/check-out status

Approval workflows

Design change orders

Release states

Integration requirements: Real-time synchronization, workflow triggers, permission mapping

Layer 2: Collaboration Tools (Communication)

What they do: Team communication, document sharing, project coordination

Common systems:

Microsoft Teams

Slack

Email (Outlook, Gmail)

SharePoint

Confluence

Notion

Data exchanged:

Design discussions and decisions

File sharing and reviews

Meeting notes and action items

Project updates

Questions and answers

Integration requirements: Searchable archives, file link sharing, notification routing

Layer 3: Business Systems (Operations)

What they do: Enterprise resource planning, customer management, supply chain

Common systems:

ERP (SAP, Oracle, Microsoft Dynamics)

CRM (Salesforce, HubSpot)

MRP/MES systems

Quality management (QMS)

Supply chain management

Data exchanged:

BOM data to manufacturing

Cost estimates to finance

Part numbers to inventory

Product specifications to sales

Quality data to engineering

Integration requirements: Data transformation, scheduled sync, error handling

Layer 4: Knowledge Management (The Missing Link)

What it does: Capture, organize, and surface tribal knowledge and design rationale

What's broken:

Design decisions live in email threads

Failure knowledge exists only in heads of senior engineers

"Why" behind designs is undocumented

Past project learnings are inaccessible

Context switching to find information wastes 6-8 hours/week

Data needed:

Design rationales and decisions

Lessons learned from past projects

Failure modes and workarounds

Vendor performance history

Manufacturing constraints

Integration requirements: AI-powered semantic search, automated knowledge capture, proactive knowledge delivery

Key Insight: Most companies integrate Layers 1-3 reasonably well. Layer 4 (knowledge management) is where enterprise integration fails, and where the biggest productivity gains exist.

The Cost of Poor Integration

Quantifying the problem makes the ROI of integration obvious.

Time Waste: Engineers as Information Hunters

Typical engineer's information search pattern:

Question: "What material did we use for the housing on Product X?"

Search process:

Check PDM vault (5 minutes) - find part file but no material notes

Search email for "Product X material" (8 minutes) - too many results

Check Slack history (6 minutes) - find discussion but no conclusion

Look in SharePoint project folder (7 minutes) - outdated specs

Ask colleague who worked on it (wait 2-4 hours for response)

Total time: 26 minutes active searching + 2-4 hours waiting = Lost productivity and broken focus

Scale to team:

200 engineers × 8 searches/day × 20 minutes average = 26,667 hours/year

26,667 hours × $85/hour = $2,266,695 in search time waste

Data Silos: Knowledge Trapped in Disconnected Systems

Where critical engineering knowledge lives:

Design rationales: Engineer's head (70%), Email (20%), PDM comments (10%)

Failure lessons: Engineer's head (80%), Meeting notes (15%), Nowhere (5%)

Vendor issues: Email threads (60%), Engineer's head (30%), Shared drive (10%)

Manufacturing constraints: Production floor knowledge (70%), Email (20%), Specs (10%)

Impact: New engineers can't access this knowledge. Onboarding takes 9-12 months instead of 3-4 months. Mistakes repeat because lessons aren't accessible.

Version Control Chaos: "Which File is Current?"

Common scenario:

Latest CAD file in PDM vault

Newer version emailed around for quick review

"Final" version in SharePoint project folder

Production using different version from last release

Consequences:

Manufacturing builds wrong version

Customer gets incorrect specifications

Engineers make changes to outdated files

Quality issues from version mismatches

Cost: One version control error causing production rework = $50K-$500K

Collaboration Friction: Information Doesn't Flow

The broken telephone game:

Engineering makes design change

Change doesn't sync to ERP

Manufacturing orders wrong components

Production line stops waiting for correct parts

3-day delay costs $180K in lost production

Root cause: Systems don't talk to each other. Changes require manual entry in multiple places. Human error is inevitable.

Security Risks: Data in Uncontrolled Locations

How it happens:

Engineer can't find file in PDM

Searches email, finds outdated version

Works on outdated file, sends via email

File now exists outside PDM control

No audit trail, no access control

Consequences:

IP leaked to unauthorized users

Regulatory compliance violations

Unable to prove data lineage

Security audit failures

Cost: Single IP leak or compliance violation = $500K-$5M+ in legal/regulatory costs

PDM Integration Best Practices

Product Data Management is the foundation. Get this right first.

SOLIDWORKS PDM Professional vs. Standard

When to use PDM Standard:

Single-site deployment

<50 users

Basic version control needs

Limited workflow requirements

Budget constraints

When to use PDM Professional:

Multi-site deployment

50+ users

Complex approval workflows

Advanced search requirements

Integration with ERP/PLM

Enterprise-grade security needs

Migration consideration: Most enterprises outgrow PDM Standard within 2-3 years. Plan for Professional from the start if you anticipate growth.

Vault Structure and Organization

Best practices:

Single vault vs. multiple vaults:

Single vault: Easier administration, unified search, simpler permissions

Multiple vaults: Better performance at scale, separate security domains, isolated product lines

Recommendation for 200+ seats: Multiple vaults by division or product line, with federated search across all vaults

Folder structure:

/Projects

/Active

/Product-A

/Product-B

/Archived

/Templates

/Libraries

/Standard-Parts

/Purchased-Components

/Administration

/Workflows

/Templates

Critical rules:

Never store CAD files outside vault

Use consistent naming conventions

Leverage folder permissions, not file-level

Archive completed projects annually

Regular cleanup of orphaned files

Workflow Automation

What to automate:

Design release workflow:

Engineer submits design for review

Auto-notify design lead

Lead approves/rejects with comments

Auto-transition to manufacturing review

Manufacturing approves/rejects

Auto-transition to released state

Auto-notify all stakeholders

Change order workflow:

Change request initiated

Impact assessment auto-assigned to relevant engineers

Approval routing based on change magnitude

Implementation tracking

Verification and release

Benefits:

60% reduction in approval cycle time

Audit trail automatically created

No changes fall through cracks

Consistent process across organization

Permission and Access Control

Role-based access control (RBAC) structure:

Roles:

Engineers: Read/write to projects, read-only to released

Senior Engineers: All engineer permissions + approval authority

Manufacturing: Read-only CAD, read/write to manufacturing data

Management: Read all, approval authority

IT/Admin: Full access for administration

Best practices:

Group-based permissions, not individual users

Least privilege principle (minimum access required)

Regular access reviews (quarterly)

Automated deprovisioning when employees leave

Audit logging of all access and changes

Search and Retrieval Optimization

Why PDM search often fails:

Keyword-based only (doesn't understand context)

Searches filenames and metadata, not content

No semantic understanding

Results not ranked by relevance

How to improve:

Traditional approach:

Mandate metadata entry (rarely followed)

Standardized naming conventions (partially adopted)

Detailed folder organization (becomes complex)

AI-enhanced approach:

Semantic search understands design intent

Searches file content, not just names

Learns from usage patterns

Ranks results by relevance and recency

Natural language queries: "show me housings for Product X"

Impact: Search time reduced from 15-30 minutes to <30 seconds

PLM System Integration

Enterprise PLM connects engineering to the entire product lifecycle.

Top PLM Systems for SOLIDWORKS Integration

PLM System | Best For | SOLIDWORKS Integration | Typical Cost |

PTC Windchill | Aerospace, defense, industrial | Native integration, strong | $800-1,200/seat |

Siemens Teamcenter | Automotive, high-volume mfg | Excellent, comprehensive | $1,000-1,500/seat |

Dassault ENOVIA | Companies in Dassault ecosystem | Native (same company) | $900-1,400/seat |

Arena PLM | Electronics, cloud-first orgs | Good, cloud-native | $600-900/seat |

Aras Innovator | Flexibility/customization needs | Strong, open architecture | $400-700/seat |

Selection criteria:

Industry fit and reference customers

SOLIDWORKS integration maturity

Scalability to your growth plans

Cloud vs. on-premise requirements

Total cost of ownership (licensing + implementation + maintenance)

Integration Patterns and Architectures

Pattern 1: Direct Integration

SOLIDWORKS plugin communicates directly with PLM

Real-time synchronization

Tight coupling, best performance

More complex to maintain

Pattern 2: Middleware Integration

Integration platform (e.g., MuleSoft, Dell Boomi) sits between systems

Transforms data between SOLIDWORKS/PDM and PLM

Loose coupling, easier to change

Additional infrastructure required

Pattern 3: File-Based Integration

Scheduled export/import of files and metadata

Simplest to implement

Batch processing, not real-time

Risk of sync issues

Recommendation for 200+ seats: Combination of Pattern 1 (real-time CAD data) and Pattern 2 (business data) with proper error handling and monitoring

Data Synchronization Strategies

What to sync:

Part metadata (number, description, material, etc.)

BOM structure (as-designed vs. as-manufactured)

Document references (specs, drawings, certifications)

Change orders and revision history

Approval status and workflow states

Sync frequency:

CAD metadata: Real-time on check-in

BOM data: On release state change

Change orders: Real-time

Reference documents: On-demand or daily batch

Conflict resolution:

Define system of record for each data type

One-way sync where possible (reduces conflicts)

Automated conflict detection with manual resolution

Clear escalation path for sync failures

BOM Management Across Systems

The BOM challenge: Engineering BOM (EBOM) in SOLIDWORKS ≠ Manufacturing BOM (MBOM) in ERP

Differences:

EBOM: As-designed, component-centric, hierarchical

MBOM: As-manufactured, process-centric, includes consumables/labor

Integration approach:

EBOM generated from SOLIDWORKS assembly

EBOM synced to PLM on release

Manufacturing transforms EBOM → MBOM in PLM

MBOM synced to ERP for production planning

Critical success factors:

Clear ownership (engineering owns EBOM, manufacturing owns MBOM)

Version control and change tracking

Automated validation (flag mismatches)

Regular reconciliation between systems

Knowledge Management Integration: The Missing Layer

Most enterprises integrate data systems but not knowledge systems. This is the biggest gap.

The Knowledge Integration Problem

Where engineering knowledge actually lives:

Explicit knowledge (documented, 30%):

CAD files in PDM

Specifications in SharePoint

Test reports in quality system

BOM in PLM/ERP

Tacit knowledge (undocumented, 70%):

Design rationales: "Why did we choose this approach?"

Failure lessons: "What have we tried that didn't work?"

Vendor quirks: "Which suppliers are reliable for what?"

Manufacturing constraints: "What's actually feasible vs. theoretical?"

Workarounds: "How do we solve recurring issues?"

The gap: Traditional integration connects explicit knowledge. Tacit knowledge stays trapped in heads and scattered across email/Slack.

Impact: New engineers take 9-12 months to productivity because they can't access the 70% of knowledge that matters most.

Integrating Email and Discussions with Design Data

The problem: Critical design decisions happen in email. That knowledge never makes it to PDM or PLM.

Traditional approach:

Ask engineers to copy important emails to PDM (rarely happens)

Link emails to CAD files manually (too much work)

Hope someone remembers where the discussion happened

AI-powered approach:

Email threads automatically indexed and linked to relevant CAD files

Semantic search finds design discussions across email + PDM + Slack

Natural language queries: "Why did we change the housing design on Product X?"

Answer includes relevant emails, PDM revisions, and meeting notes

Implementation:

Connect email system (Office 365, Gmail) to AI knowledge platform

Index historical emails (with privacy controls)

Link discussions to CAD files based on content analysis

Surface relevant context automatically during design work

Connecting Meeting Notes to Projects

The problem: Design reviews, technical discussions, and decisions happen in meetings. Notes live in OneNote, Confluence, or someone's notebook.

What to capture:

Design review decisions and action items

Technical discussions and alternatives considered

Failure analysis meetings

Lessons learned sessions

Integration approach:

Manual (baseline):

Meeting notes template in Confluence

Engineer links to relevant PDM files

Adoption: 20-30%

Automated (AI-powered):

Meeting recordings auto-transcribed

Key decisions and action items extracted

Auto-linked to relevant projects and CAD files

Searchable along with all other engineering knowledge

Impact: Design rationale accessible to future engineers instead of lost when meeting attendees leave company

Slack/Teams Integration for Design Discussions

The problem: Quick questions and answers happen in Slack/Teams. This knowledge disappears in chat history.

Value of Slack/Teams knowledge:

Real-time problem-solving

Workarounds and quick fixes

Vendor and supplier insights

"Ask the expert" tribal knowledge

Integration approach:

Basic:

Dedicated channels per project

Pin important messages

Search history when needed

Value: Limited (still requires manual search)

Advanced (AI-powered):

All Slack/Teams discussions indexed alongside PDM data

Semantic search across chat + email + files

Proactive surfacing: "3 people discussed this issue in #mechanical-design channel last month"

Link discussions to CAD files automatically based on content

Implementation:

Connect Slack/Teams to knowledge platform

Index channel history (with privacy controls)

Enable cross-platform search

Surface relevant discussions during design work

AI-Powered Knowledge Assistants: The Integration Layer

The insight: AI can be the unifying integration layer that connects everything.

How it works:

AI indexes all connected systems (PDM, PLM, email, Slack, SharePoint, etc.)

Understands relationships between different data types

Provides unified search across all systems

Answers questions in natural language

Surfaces relevant context proactively during design work

Example workflow:

Engineer working in SOLIDWORKS asks: "Why did we use stainless steel instead of aluminum for the XR-500 housing?"

AI searches across:

PDM vault (revision history and comments)

Email (discussions about material selection)

Slack (real-time conversations during design phase)

Meeting notes (design review decisions)

Test data (material testing results)

AI responds: "Stainless steel was selected for corrosion resistance in marine environments. Aluminum was initially considered but failed salt spray testing (Test Report TR-2022-045). Discussion thread: [email link]. Design review decision: [meeting notes link]. See also similar decision on Product Y."

Impact:

Answer in <30 seconds instead of 2-4 hours of searching

No context switching from SOLIDWORKS to 5 different systems

Complete design rationale accessible, not just fragments

This is what Leo AI provides: Unified knowledge layer that integrates all enterprise systems and makes engineering knowledge instantly accessible.

Enterprise Architecture for SOLIDWORKS

Reference Architecture Diagram

┌─────────────────────────────────────────────────────────┐

│ Engineer Workstation │

│ ┌─────────────────────────────────────────────────┐ │

│ │ SOLIDWORKS + Leo AI Plugin │ │

│ └─────────────────────────────────────────────────┘ │

│ │ │

│ ▼ │

└──────────────────────┬────────────────────────┬─────────┘

│ │

┌───────────▼────────┐ ┌─────────▼──────────┐

│ PDM/PLM Layer │ │ AI Knowledge │

│ - SOLIDWORKS PDM │ │ Integration │

│ - Windchill/ │◄───┤ Platform │

│ Teamcenter │ │ (Leo AI) │

└───────────┬────────┘ └─────────┬──────────┘

│ │

┌───────────▼────────┐ │

│ Collaboration │ │

│ - Email (O365) │◄────────────┤

│ - Slack/Teams │ │

│ - SharePoint │ │

└───────────┬────────┘ │

│ │

┌───────────▼────────┐ │

│ Business Systems │ │

│ - ERP │◄────────────┘

│ - CRM │

│ - MRP/MES │

└────────────────────┘

Authentication and SSO Integration

Requirements for 200+ seat deployment:

Single Sign-On (SSO) across all systems

Centralized identity management

Multi-factor authentication (MFA)

Role-based access control (RBAC)

Automated provisioning/deprovisioning

Typical architecture:

Identity Provider (IdP):

Azure Active Directory (Microsoft ecosystem)

Okta (multi-platform)

Active Directory + ADFS (on-premise)

SSO Protocol: SAML 2.0 or OAuth 2.0 / OpenID Connect

Integration points:

SOLIDWORKS PDM: ADFS or Azure AD integration

PLM systems: Native SAML support

Leo AI: OAuth 2.0 with IdP

Collaboration tools: Native O365/Google integration

Business systems: SAML federation

Permission synchronization:

Active Directory groups mapped to PDM permissions

Same groups control PLM access

Unified access control across all systems

Changes in AD automatically propagate

API Strategies for Custom Integrations

When you need custom APIs:

Unique business processes not supported out-of-box

Legacy system integration

Custom reporting and analytics

Workflow automation beyond standard capabilities

SOLIDWORKS API options:

SOLIDWORKS API (COM-based, VBA/C#/C++)

PDM Professional API (.NET, COM)

eDrawings API (viewer integration)

PLM system APIs:

REST APIs (most modern PLMs)

SOAP/Web Services (legacy systems)

Native SDKs (vendor-specific)

Best practices:

API versioning strategy (handle upgrades)

Error handling and retry logic

Rate limiting and throttling

Logging and monitoring

Security: API keys, OAuth tokens, proper encryption

Example integration: Custom tool that syncs SOLIDWORKS custom properties to PLM fields not mapped by standard integration

Cloud vs. On-Premise Considerations

Decision factors:

Factor | On-Premise | Cloud | Hybrid |

Data sovereignty | Full control | Limited control | Mixed |

Security customization | Complete | Limited | Mixed |

Capital costs | High upfront | Low upfront | Medium |

Operational costs | Internal IT burden | Subscription fees | Both |

Scalability | Manual, planned | Elastic, automatic | Manual + elastic |

Disaster recovery | Manual implementation | Built-in | Mixed |

Performance | LAN speed | Internet-dependent | Mixed |

Maintenance | Internal responsibility | Vendor-managed | Split |

Recommendation for 200+ seats:

CAD files and PDM: On-premise or private cloud (performance-critical, large files)

PLM system: Cloud or hybrid (vendor-managed, accessible from anywhere)

Collaboration tools: Cloud (Microsoft 365, Google Workspace)

AI knowledge platform: Cloud with on-premise connector (leverages cloud AI, data stays secure)

Security and Compliance Requirements

For enterprise SOLIDWORKS deployments:

Data classification:

Public: Marketing materials, published specs

Internal: General engineering documents

Confidential: Unreleased designs, IP

Restricted: Defense, medical, highly regulated

Security controls by classification:

Encryption at rest (AES-256)

Encryption in transit (TLS 1.2+)

Access controls (RBAC)

Audit logging

Data loss prevention (DLP)

Compliance requirements:

ITAR (Defense contractors):

U.S. persons only access

Geographic restrictions on data

Detailed audit trails

Government-approved systems

ISO 27001 (Information security):

Risk assessment and management

Security policies and procedures

Incident response plans

Regular audits

SOC 2 Type II (Service organizations):

Security, availability, confidentiality

Third-party audited

Continuous monitoring

GDPR (European operations):

Data minimization

Right to erasure

Data portability

Privacy by design

Learn more about Leo AI enterprise security

Implementation Roadmap

Phase 1: Assessment (Weeks 1-2)

Week 1: Current state mapping

Inventory all systems engineers use

Document data flows between systems

Identify integration gaps and pain points

Survey engineers on biggest frustrations

Deliverables:

System inventory with usage data

Data flow diagrams

Gap analysis report

Pain point prioritization

Week 2: Requirements gathering

Define integration objectives and success metrics

Security and compliance requirements

Performance requirements (latency, throughput)

Scalability requirements (growth projections)

Deliverables:

Integration requirements document

Success criteria and KPIs

Compliance checklist

Budget and timeline estimates

Phase 2: Architecture Design (Weeks 3-4)

Week 3: Integration architecture

Design overall system architecture

Select integration patterns for each connection

Define data synchronization strategies

Plan error handling and monitoring

Deliverables:

Architecture diagrams

Integration specifications

Data mapping documents

Error handling procedures

Week 4: Security architecture

Design authentication and authorization approach

Define data encryption strategy

Plan audit logging and compliance monitoring

Design disaster recovery and backup strategy

Deliverables:

Security architecture document

Authentication flows

Encryption specifications

DR/backup plan

Phase 3: Pilot Implementation (Weeks 5-8)

Week 5-6: Core integrations

Implement PDM/PLM integration

Configure SSO and authentication

Set up basic workflow automation

Deploy to pilot team (20-30 engineers)

Week 7: Knowledge management layer

Deploy AI knowledge platform

Index PDM vault and email

Configure search and retrieval

Train pilot team on usage

Week 8: Testing and validation

Performance testing

Security testing

User acceptance testing

Issue identification and resolution

Deliverables:

Functioning pilot system

Test results and issue log

User feedback report

Go/no-go decision for full rollout

Phase 4: Full Rollout (Weeks 9-16)

Week 9-12: Enterprise deployment

Roll out to all engineering teams in phases

Migrate historical data

Train all users

Establish support processes

Week 13-14: Business system integration

Integrate with ERP/CRM/MRP

Configure BOM synchronization

Set up change order workflows

Test end-to-end processes

Week 15-16: Optimization and handoff

Performance tuning

Monitor and resolve issues

Document system and procedures

Transition to operational support

Deliverables:

Fully integrated enterprise system

Complete documentation

Trained users and administrators

Operational runbook

Measuring Integration Success

System Performance Metrics

Response time:

PDM check-in/check-out: <5 seconds (target)

Search across all systems: <2 seconds (target)

PLM data sync: <10 seconds for real-time (target)

Availability:

PDM vault uptime: 99.9% (target)

Integration platform uptime: 99.5% (target)

AI knowledge platform: 99.9% (target)

Data quality:

Sync success rate: >99% (target)

Conflict resolution rate: <0.1% manual intervention (target)

Data validation errors: <0.5% (target)

User Productivity Metrics

Search time reduction:

Baseline: 15-30 minutes average per search

Target: <30 seconds with AI-powered unified search

Annual value: $2M+ for 200-person team

Context switching reduction:

Baseline: 13 switches per hour

Target: <8 switches per hour

Annual value: $1.3M+ for 200-person team

Knowledge access:

% of questions answered without asking colleagues: 70%+ (target)

New engineer onboarding time: 3-4 months vs. 9-12 months baseline

Annual value: $500K+ in faster productivity

Business Impact Metrics

Design cycle time:

% reduction in design iterations: 30-40% (target)

Time from concept to release: 25% reduction (target)

Quality improvements:

% reduction in repeated design mistakes: 60% (target)

Field failure rate: 35% reduction (target)

Cost savings:

Reduced prototyping costs: $200K-$500K annually

Avoided design rework: $500K-$1M annually

Time-to-market improvement value: $2M-$5M per product

ROI Calculation

Investment for 200-seat deployment:

PDM/PLM software: $500K-$800K (3-year)

AI knowledge platform: $300K-$500K (3-year)

Integration services: $200K-$400K (one-time)

Training and change management: $100K-$200K

Total investment: $1.1M-$1.9M over 3 years

Annual value:

Search time savings: $2M

Context switching reduction: $1.3M

Faster onboarding: $500K

Reduced errors: $500K-$1M

Total annual value: $4.3M-$4.8M

ROI: 2.3-4.4x in year 1, compounding in subsequent years

Common Integration Challenges and Solutions

Challenge 1: User Adoption Resistance

Why it happens: Change is hard; new systems seem complicated; "old way worked fine"

Solutions:

Show immediate value (faster search, less context switching)

Start with enthusiastic early adopters

Provide hands-on training, not just documentation

Celebrate quick wins and success stories

Get executive sponsorship and visible support

Make it easier than old way, not just better

Challenge 2: Legacy Data Migration

Why it happens: Years of unstructured data in old systems; inconsistent formats; missing metadata

Solutions:

Phased migration (current projects first, archive later)

Data cleansing before migration (don't migrate garbage)

Automated migration tools where possible

Manual review for high-value data

Accept that 100% migration isn't necessary

Prioritize 20% of data that gets 80% of usage

Challenge 3: Performance Issues at Scale

Why it happens: Integration overhead; large file sizes; concurrent users; network latency

Solutions:

Caching strategies for frequently accessed data

Asynchronous processing for non-critical sync

Database indexing and query optimization

Content delivery network (CDN) for distributed teams

Hardware upgrades if necessary

Monitor and optimize continuously

Challenge 4: Security Concerns with Connected Systems

Why it happens: More integration points = more attack surface; data flowing between systems; cloud concerns

Solutions:

Zero-trust security model (verify everything)

Encryption everywhere (at rest and in transit)

Principle of least privilege for all integrations

Regular security audits and penetration testing

Monitor all integration points

Incident response plan for breaches

Challenge 5: Maintaining Custom Integrations

Why it happens: Vendor updates break integrations; custom code becomes technical debt; original developer leaves

Solutions:

Minimize custom code (use standard connectors when possible)

Comprehensive documentation of custom integrations

Automated testing for all custom components

Version control and change tracking

Regular refactoring to reduce complexity

Consider replacing custom with standard as vendors improve

Your Next Steps

Enterprise SOLIDWORKS integration isn't optional anymore. Companies with connected systems design better products faster, onboard engineers in months instead of years, and prevent millions in repeated mistakes.

The difference between leaders and followers is execution.

Start here:

Assess your current state - Map your systems and integration gaps

Calculate your cost - Quantify waste from poor integration

Design your architecture - Plan holistic integration, including the knowledge layer

Pilot with AI knowledge management - Biggest ROI, fastest time-to-value

The technology exists today. The question is whether you'll implement it before your competitors do.